Cryogenic Food Freezing

Using liquid nitrogen to freeze food products while preserving, freshness, safety and quality of the food and minimising costs

Cryogenic food freezing uses liquid nitrogen to effectively freeze the food products. This helps food manufacturers to maximise production efficiencies while minimising costs.

The use of cryogenic gas at very low operating temperatures of -80ºC provides a high heat transfer rate that ensures quick freezing times. As a result, cryogenic freezing delivers production efficiencies alongside measurable product quality improvements, particularly in relation to losses due to dehydration.

Cryogenic freezing also maintains the natural quality of food. When a product is frozen, ice crystals are formed. The smaller and more evenly distributed the crystals, the better the quality and taste of the frozen product. The only way to ensure that small crystals form uniformly throughout the food product, both inside and outside the cells, is to quick-freeze the food at cryogenic temperatures.

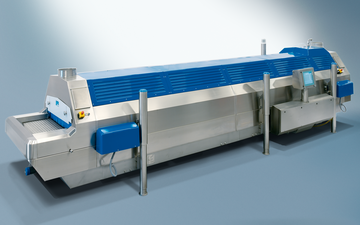

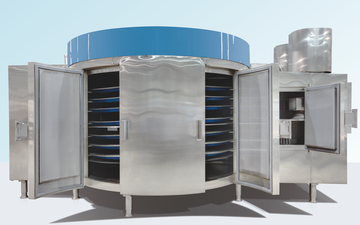

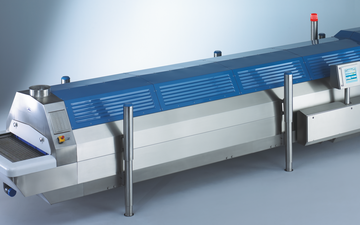

There are several different cryogenic food freezing methods. Food type and amount of physical manufacturing space are key factors in deciding which specialised freezer type is most suitable.