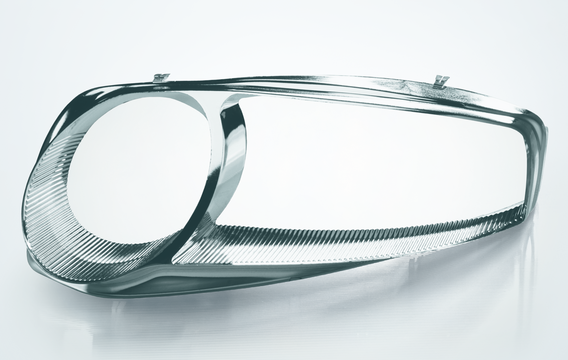

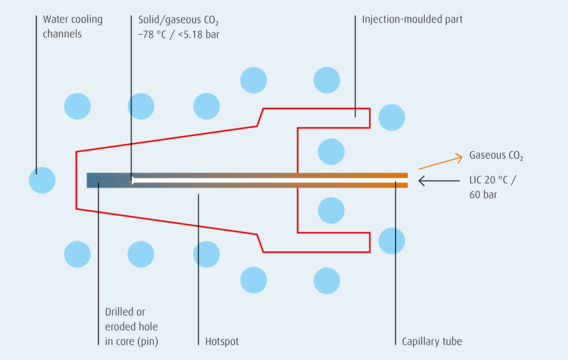

Our PLASTINUM® Spot Cooling solution advances temperature control in injection moulding by ensuring uniform temperature distribution on the mould cavity surface. It uses liquid carbon dioxide (LIC) as an effective cooling medium for hotspots. Comprising control devices, distributors, solenoid valves and capillary tubes, our spot cooling package can be easily retrofitted to existing installations.

Supplementing conventional water cooling, this patented solution is ideal for areas of injection-moulded products that are difficult to access or prone to material accumulation. In other words, areas where water or other cooling methods are ineffective or cannot be implemented.

PLASTINUM Spot Cooling can accelerate cycle times by up to 50% depending on the part geometry and material. In addition, carbon dioxide (CO₂) results in more even temperature distribution along the mould surface. This greatly enhances the quality of the moulded part by eliminating surface defects, sink marks and warpage.